Efficiency and optimisation

Total Productive Management

Medium-sized companies, of which nass magnet GmbH is one, make up a large share of the economic power in Germany. They also play a leading role in the industries where they are active, both in Europe and worldwide — sometimes even occupying the market leading position. These companies are characterised not only by their interesting product ranges, but also by their efficient decision-making channels and, as a result, faster response times. These are just some of the many points that make nass magnet a promising company.

Total Productive Management for medium-sized companies

Today, however, it is no longer sufficient to bring to the market a successful product range in order to stay competitive in the long term. New technologies, demographic change, the globalisation of markets and shorter product life cycles are consistently presenting modern companies with new challenges.

In order to cope with these challenges, it is essential for companies to develop and structure themselves in a more future-proof way. One tool for strengthening and developing corporate structure is „Total Productive Management“. Total refers to the holistic approach which extends across all departments and management levels in a company. Productive stands for visualising and reducing losses in processes. Management stands for the appropriate path to achieving the desired goal.

Total Productive Management (TPM) is a management tool designed to achieve overriding goals such as maximising efficiency, performance and productivity. This will be accomplished through optimal interaction between people, machines and their environment. Available resources will be pooled and used in the most optimal way.

From Maintenance to Management

TPM was originally developed for the Japanese automotive industry as preventative management for systems and maintenance, and, 50 years ago, had a different meaning: „Total Productive Maintenance“. Maintenance was the primary focus at that time. Experience gained over the course of years, however, showed that solving complex problems or tasks quickly and efficiently required pooling all resources and skills from every department within a company.

The basic idea of modern Total Productive Management is to create a system that contributes to continuously improving processes within the whole company. TPM improves the overall efficiency of production facilities, as well as a company‘s overall productivity. It also ensures workflows are optimised with active involvement of the employees. In contrast to its predecessor „Total Productive Maintenance“, „Total Productive Management“ is not intended to be solely limited to production and maintenance. This is why „Total Productive Maintenance“ developed into „Total Productive Management“.

Goals of TPM: Improvement across all company departments

(Maximise efficiency, performance, productivity)

- Increase systems availability

- Reduce waste

- Improve communication

- Avoid unnecessary tasks

- Achieve more through your work

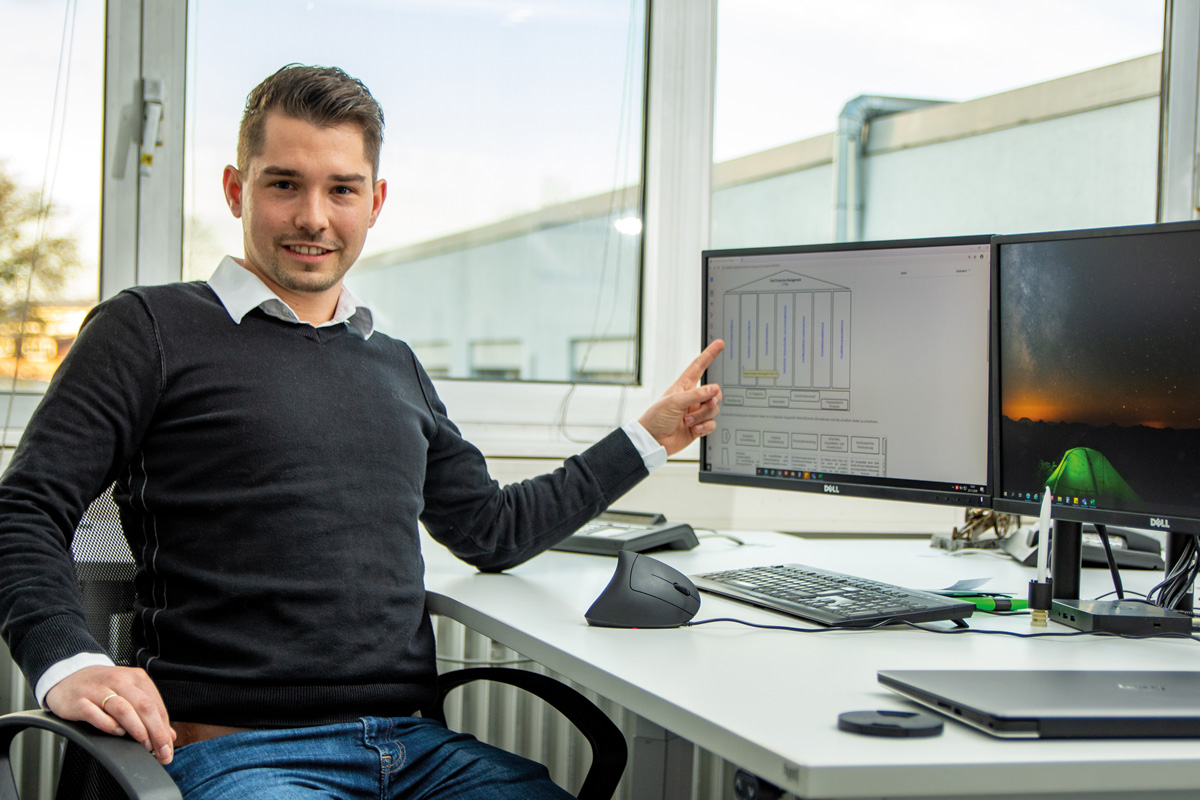

The NM TPM company

Total Productive Management at nass mag-net stands on a solid foundation that represents the ideal conditions, or basis, for successful Total Productive Management. It is shaped by visualisation, the 5S programme (Sort, Set in Order, Shine, Standardise, and Sustain), figures, interface work and standardised processes. There are seven pillars based on this foundation, which correspond to different areas of the company. The basic idea of TPM and its associated goals form a roof over the pillars.

Conclusion

The invention of „Total Productive Management“ aims not only to optimise maintenance but also to create a suitable interconnection between all the departments in a company and production and maintenance. Consistently reducing waste (e.g. scrap, production time etc.) allows efficiency in a company to be increased. Introducing TPM is an important step towards shaping the future and ensuring success for the company group nass magnet.

TPM thrives on continual improvement and, over the course of time, will adapt to new circumstances again and again. You can find this development, along with a detailed description of the individual pillars, in our quality management system in Confluence, our wiki software.

TPM is currently in its introductory phase. Some pillars have already been introduced and the foundations for other pillars have already been laid. One positive effect is already being observed —there has been a reduction in the backlog and an increase in machine availability in production.

Christopher Winkler

Head of production management,

nass magnet GmbH