IO-Link

IO-Link

Digitization and the growing technological progress in industry are not only making production processes faster and more flexible, but are also creating an extensive variety of data in today's modern production lines.

Smart devices used generate a constantly growing amount of data and communicate on an international and fieldbus-independent IO-Link standard. The integration of IO-Link technology makes it particularly easy to evaluate and use this data. The bidirectional communication between the IO-Link devices enables both extended diagnostics and rapid parameterization of the equipped machines and systems.

Time and cost savings, increases in flexibility and productivity - IO-Link offers more than just one reason for extensive use in production.

The future of production begins today.

Standardized worldwide, manufacturer-independent and regardless of the fieldbus: IO-Link opens the way to complete automation of production.

The fast exchange of process, service and event data between the IO-Link devices and the IO-Link master enables simple control, diagnosis and parameterization of machines and systems. This reduces downtimes, increases efficiency and makes production fit for the future.

Standardizing together

As one of the leading international manufacturers of solenoid valves and electromagnetic solutions, technological progress and the continuous further development of our company group and our products is at the top of our agenda.

With an eye toward the future, we also want to help shape the next step in the industry. IO-Link will be the first technology to prepare the way to Industry 4.0 - for nass magnet and our customers.

How does IO Link work?

IO-Link describes the first digital and worldwide manufacturer and device independent communication standard for sensors and actuators.

An IO-Link is based on the conventional 3-wire connection, which can communicate independently of the fieldbus. With this point-to-point communication, no additional cable material requirements are necessary. Due to the compatibility of IO-Link with the existing 3-wire system with the sensors to be switched in the machines and systems, retrofitting of the machines is also possible in case of spare parts or rewiring.

The bidirectional communication enables both extended diagnostics of the sensors and actuators and simple and fast parameterization. Furthermore, IO-Link communication allows one or more measured or analog values to be transmitted in addition to the switching signal. This leads to a significant acceleration of commissioning due to the reduced variety of types.

Due to the fieldbus-independent mapping, IO-Link can be integrated into the usual and already existing automation systems.

IO-Link in use with nass magnet

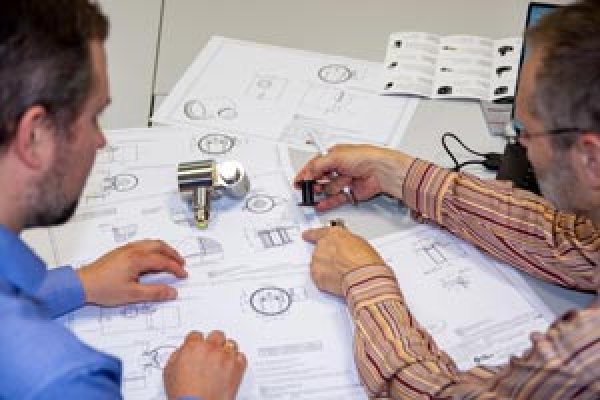

As one of the leading international manufacturers of solenoid valves and electromagnetic solutions, technological progress and the continuous further development of our group of companies and our products are at the top of the agenda.

With an eye to the future, we also want to help shape the next step in the industry. IO-Link will be the first technology to pave the way to Industry 4.0 - for nass magnet and for our customers. This is why our experts are working around the clock on the further development of our products, always focusing on the transition to smart production.

With our valve connector with IO-Link interface and Smart Actor profile, we offer our customers a first opportunity to take the step into automation and make production more efficient and flexible.

Connected valves can be controlled and monitored via the network using the IO-Link interface, so that remote diagnostics and parameterization can reduce maintenance costs, increase efficiency and make production more flexible.

IO-Link benefits at a glance

- IO-Link is a communication standard that can be integrated worldwide and independent of the fieldbus (according to the IEC 61131-9 standard)

- Data storage, parameterization, extended diagnostics, reduced cabling possible

- Cost reduction of downtime and maintenance

- Transparent representation of the IO-Link system down to the lowest field level

- Availability of process, service and event data

- Identical structure of all IODD files of the master

- manufacturers for user-friendly and easy operation

- Reduced or simplified cabling of the system

- Simplified programming and more options for configuring devices during operation through ISDU (Index Service Data Unit)

Smart Connector€120.00 As low as €96.00Learn More

Smart Connector€120.00 As low as €96.00Learn More- IO-Link interface

- DIN norm interface valve connector

- Quick and easy connection

- Status monitoring, RGB LED

- Power saving with PWM mode

- Parameterization through software

- Double switching cycle counter

- Diagnostic data

- Event messages

- Data storage

- Off-line mode

pre-programmed timer and/or PWM

4-Port Ethernet IO-Link MasterOut of stockLearn More

4-Port Ethernet IO-Link MasterOut of stockLearn More- IO-Link V1.1.3 compatible Master

- Ethernet/TCP-IP interface,

- DHCP or static IP address configuration

- Standardized JSON mapping

- Node-RED integration supported

- 4 independent powered IO-Link Class A ports

- IP67 Protection

IO-Link V 1.1.3. fully backward IO-Link compatibility

Ethernet/TCP-IP interface, which is globally accepted and highly supported, making it easy to integrate with existing systems or to build a new system.